By the end of the First World War, the Swiss had made over 25 million artillery shell fuses for the British, as well as over 121 million components used in assembling other fuses. These were precision parts that required skilled labour. Other items that were produced in Switzerland for the British included 32,754 aeronautical watches, 19,920 aneroid barometers for aircraft, 75,340 magnetic or prismatic army compasses, and even parts for Rolls Royce aero engines. After the Italian entry into the war, that country also bought munitions from the Swiss.

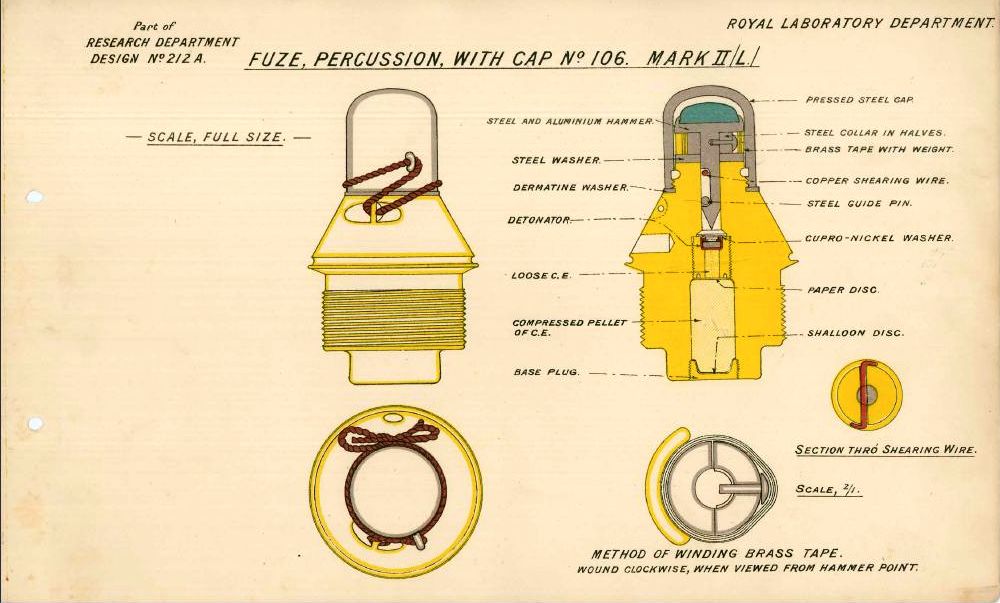

This work required considerable raw materials, but Switzerland’s natural resources were limited and she depended on trade to obtain many such supplies. For example, the Swiss imported brass for making the No.106 fuse from the USA, and steel from the UK. In an attempt to stop this trade, the Germans created a “black list” of manufacturers making munitions for the Entente (France, the UK and allies), to ensure that they could not obtain coal, steel or iron from Germany (which was the main source of these materials for Swiss factories). Swiss firms and the Swiss government tried to evade these measures, and the Germans renegotiated this agreement at later dates. For the flow of trade in the other direction, the Société Suisse de Surveillance économique was established to ensure that no metal which had been supplied to the Swiss for the production of fuses for the Entente, was sent to the Central Powers instead.

Image source: "Mili14" at collections.delcampe.net

What was the value of these Swiss-manufactured munitions to the warring powers? In 1915, shortages of artillery ammunition were blamed for difficulties suffered by British troops, in what was known as the “Shell Scandal”. Offensives during the First World War – and for most of the war, it was the Entente armies that were on the offensive – needed huge quantities of artillery shells. During the four months of the Third Battle of Ypres (1917), British forces fired some 33 million artillery shells from around 3,500 guns. Weight of firepower was vital for destroying enemy defences, including wire entanglements, communications routes and artillery batteries. It is not quite clear what proportion of shells used by the Entente during the First World War used components made in Switzerland, but the above figures suggest that their contribution was significant yet probably not decisive.

Image source: "No106MkIIFuzeRLDiagram" by Royal Laboratory - "Fuze Diagrams".Supplied by Allan Brown : British Ordnance Collectors Network http://www.bocn.co.uk. Licensed under Public Domain via Wikimedia Commons.

The quality and reliability of the fuses manufactured in Switzerland appears to have been high. In October 1918, a British inspector reported that: “In Switzerland there are whole districts such as Geneva and Le Locle whose industries are watchmaking, and whose people are therefore hereditarily trained to most accurate work. Fortunately these districts are French-speaking, and very pro-Entente. Large contracts were placed in both these districts with extremely satisfactory results... The fuzes produced by them on a very large scale gave complete satisfaction, and the rejects were only a very small percentage of the whole.”

Sources: UK National Archives, MUN 5/321B/28 and MUN 4/2026.

RSS Feed

RSS Feed